Thai-Asia P.E. Pipe Co., Ltd. was established in 1984. With 40 years of time and experience, this marks the stability and adherence to quality in our production processes and our products.

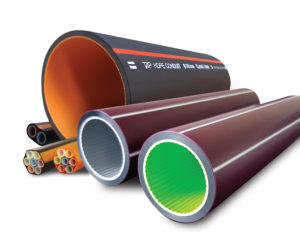

The company is capable of producing high quality HDPE pipes with diameters up to 2000 mm for smooth surface pipe, and diameter 800 mm for corrugated pipe.

In 2020, the company has expanded its production capacity to 80,000 tons per year to help meet market demands quickly and efficiently.

Company’s strengths is the flexibility of production and feedback to customers. We can produce a variety of products according to customer requirements in the form of OEM. Over the course of 40 years, we have exported our products to more than 23 countries around the world.